The RAID 2024 Committee would like to thank Shayne Harris and the Co-contributors to the RAID 2008 information website. Most of the following information for RAID 2024 has been taken directly from RAID 2008 Information.

This page contains general RAID Car Preparation Information. Here is a link to the abridged English version of Ici commence l´aventure

Contents

General Raid car preparation

It is crucial that you read this information carefully to make sure your vehicle is well prepared to handle the conditions of this Raid. The bible on raid preparation is “Ici commence l´aventure” – click to download an abridged English version of the great official Citroën publication as a pdf document. Keep in mind the most important part of vehicle preparation, as stated by Jaques Wolgensinger in the introduction

“… some parts need to be strengthened in order to withstand driving on rough terrain – but this can expose the relative weakness of an associated component… Again, caution dictates that some spares should be carried; yet they add to the overall weight, which makes the vehicle more prone to break down, which can in turn tempt you to take even more spares… to the extent where some specialists are prone to advise that the only truly indispensable items are some rags to wipe parts clean of sand and dust, and galvanised wire for everything else.”

The purpose of Raid is to enjoy the adventure and not to make it a nightmare due to lack of preparation – but, as Raider Jost once said: “When shit happens, we start to have fun.”

Preparing your 2CV or A Series Citroën for Raid Australia 2024

It is expected that before you start your Raid specific preparation, you have a fully operational and roadworthy vehicle.

The reality is that most problems that occur on Raids are a result of not driving to the conditions. Nonetheless, you do need a fully prepared vehicle.

The following Preparation checklist and details is taken from the Citroën publication Ici commence l’aventure. The modifications pointed out are those considered applicable for Australian conditions as learnt by David Gries and many other Raiders since their first Raid in 1988.

All these modifications can be done in various ways, they don’t have to be exactly the same as the book. Do not over modify or reinforce because it may break at the next weakest point.

Preparation Checklist

- Inspect Chassis and replace if required

- Fit Engine and Gearbox Pan

- Service and Replace Swing Arm Bearings

- Service and Replace worn Kingpins

- Service Suspension and adjust heights

- Suspension pots

- Shock absorbers

- Inspect and Secure Fuel and Brake lines

- Inspect and Service Steering

- Check Rubber Inner Mudguard Holders

- Bumpers

- Inspect and Service Engine

- Inspect Exhaust

- Carburettor

- Air Filter

- Wheel Bearings

- Brakes

- Tyres

- Gearbox

- Clutch

- Electrical

- UHF Radio

Preparation list detail

Chassis

History shows that a rusted chassis will often fail on Raids. Inspect the chassis closely and if there is any indication of rust or deformation replace the chassis.

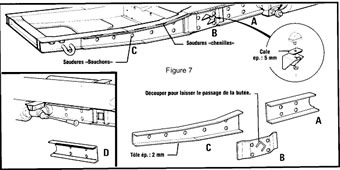

See Figure 7 in the Citroen publication Ici Commence L’aventure, for advice on how to reinforce a chassis. Most new chassis come with the PO reinforcements. If you are not familiar with the problems associated with weakening steel due to welding, refer to a specialist.

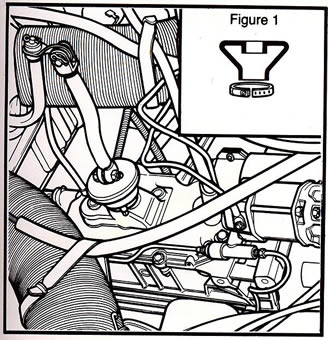

Engine and Gearbox Protection Guard

You will need to fit an engine and gearbox protection guard. Experience has shown that the best material for this job is aluminium plate around 3mm thick. The plate needs to attach to each chassis side-rail and extend from the front bumper and terminate in front of the exhaust cross box.

Drill access holes big enough for tools to reach engine mounts, lamp holder bolts, sump plug, drain plug on gearbox.

The example above has a polypropylene sheet with steel plate beneath.

Note also that the steel plate extends forward and up to the bumper bar. This worked well to push down the spinifex and keep grass and seeds from the air intake.

Note also the bonnet strap and the rope for pulling out when bogged. It is attached with shackles to the towing eyes and tucked into the tray behind the bumper.

Swing Arm Bearings

Every Raid has seen some casualties due to dry, rusted and/or loose bearings.Clean and regrease or replace the bearings and refit them to original specifications.

Kingpins

The kingpins should be inspected for play and replaced if necessary.

Suspension

The suspension is an integrated system of tyre pressure, shock absorbers and spring pot. If you adjust one, say increase the tyre pressure, you are likely to have a problem in another, in this example a cracked shock absorber mount perhaps.

Original specifications are recommended.

Suspension pots

Check the canister for rust. The spring pot mountings are often rusted. All threaded parts should be serviceable and able to be easily dismantled.

Check that the two rubber buffers are fitted to specification.

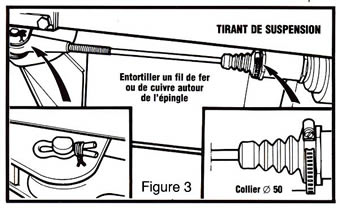

Check knife edge clips and dust boots and secure.

Cut a screwdriver slot into all suspension bolts, at the 10mm end. Should you tear the steering or axle tubes off, you can easily remove the broken bolt, especially on the rear axle.

Vehicle heights should be adjusted according to the manufacturer specifications. Changing the height to compensate for overloading the vehicle is fraught with danger. By shortening the suspension rod, you limit the travel of the arm, so when the arm rises, the spring in the pot compresses before the arm comes in contact with the bump stop. This results in broken rods, mountings being ripped off wheel arms and bent wheel arms.

Shock Absorbers

Shock Absorbers should be new, or as new, and all mountings should be inspected for fatigue cracks.

Weld a brace on to the rear suspension stop and check welding on the pulling points of all arms, we have seen these crack.

Fuel Line

The fuel line should be securely attached to the chassis. The original black fuel line clips located on the left side chassis rail are often missing or not secured to the chassis. When driving over obstacles the fuel line can be torn off.

Inspect all rubber hoses for cracks.

Brake Lines

Brakes lines should be firmly secured and inspected for cracks and rub marks.The rear brake pipes on the swing arms are completely exposed. To avoid stones hitting the pipes, fit rubber or plastic sleeves and tape the lines to the swing arms.

Steering

The axle bolts need to be serviceable and tightened to the correct torque and locked into place with the locking tabs.

All threaded parts of the track rods and track rod ends should be cleaned and serviceable.

Re-grease the tie rod ends and fit new dust boots. Check the ball joint for metal chips and secure the two 7mm bolts on the wheel hub with a lock plate. The 7mm bolts are known to fatigue so they are best replaced. Adjust the front wheels to 0-3mm toe out.

Inspect the steering pinion for play; it is not uncommon to find the pinion bearing worn out. Same for the two steering ball joints behind the gear bx. Check the anti-rattle rubber between the steering ball joints and the steering track rods.

Rubber Inner Mudguard Holders

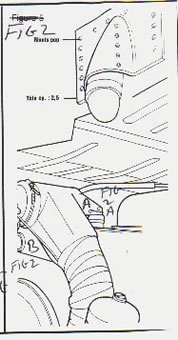

To prevent the middle drive shaft boot being ripped, secure the lower inner mudguards in their V shaped rubber holders attached on the chassis and bend the corners slightly away.

Bumpers

Bumper bars should be secured. The standard rear bumper hangs very low, and an alternate is suggested. All items like reverse lights and fog lights should be removed from under the bumper and refitted above the bumper.

Engine

Start with a compression test. It should read from 100 psi to 160 psi with a variation of not more than 10% between the two cylinders. Remove the valve covers and check the 3 main nuts holding the cylinder heads. Adjust the valves to 0.20mm and fit new valve cover seals.

Fit new contact points, condenser, spark plugs and ignition leads. If you have electronic ignition fitted be sure to bring a complete original Citroën points and condenser set including the box, advance weights and fittings. It is possible the ignition system will be submerged. Clean the oil cooler. Inspect the oil feeding tube on the engine and on both cylinder heads for rust and oil leaks.

Fit new engine mounts; inspect the fan hub for cracks and replace if necessary. Inspect the fan protective grill for defects and make sure the light grill mesh on the inside of the bonnet is firmly secured to prevent stones and twigs entering the fan cooling shield. Test the engine breather. Change the oils and oil filter.

Exhaust

Inspect all inlet and exhaust manifold nuts and exhaust clamps.Make sure that both mufflers are in good condition and the front muffler is hanging correctly on the two bolts on the gear box.

Carburettor

The carburettor should be serviced and adjusted according to original specifications.

Air Filter

The air filter housing is constructed from two parts; joined together and should be sealed with a sealant. If the housing is aged and worn replace it.

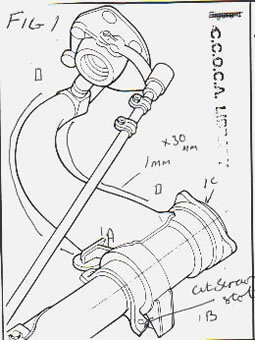

Secure the goose neck hose connecting the air filter to the carburettor using clamps. If the goose neck is cracked replace it.

Wheel Bearings

Inspect all four wheel bearings for play and noise. Bearings should be re-greased or replaced.

Brakes

Must be in serviceable condition and adjusted to specification. Change the brake fluid.

Tyres

The choice is a point of conjecture.

The original tyre is a Michelin 125×15, however the side walls are angled and susceptible to piercing. Michelin 135×15 have proved to be a suitable tyre, however other 135×15 tyres and even 145×15 tyres have performed equally well.

The larger the tyre, the more unsprung weight, and the larger the alteration to engine to wheel ratio. The single most important factor remains the age of the tyre, not the amount of tread left, but the age of the rubber. New tyres are recommended.

Gear Box

Gear box trouble occurs on every Raid. Gearboxes unwind and lock or simply fail. The gearbox should be in serviceable condition.You should ensure that the gearbox has been re-peened, by approaching your local gear box guru, and avoid unwinding the box.

Inspect the lid rubber boot for cracks and secure with cable tie or clamp. Check the two rubber grommets on the gear lever linkage and inspect all bolts, nuts, split pins and washers.

Clutch

If the engine is not in the car, inspect the entire clutch for wear and tear.

While you are there check the spigot bush and seal at the back of the crank shaft and the crank shaft seal behind the fly wheel.

It is best to have the fly wheel professionally machined. Fit a new clutch and clutch cable. Inspect the clutch fork for cracks or bends and replace if necessary.

Electrical

You may think your alternator, starter, regulator and battery are in good condition and have not failed you for years, but now is the time to get your alternator and starter overhauled and replace your regulator and battery.

UHF Radio

A vehicle-mounted UHF (minimum 40 channel) radio and antenna must be fitted to every car in the Raid.

Some of the sections that we travel have a condition of transit being that each vehicle is fitted with such a radio which operates between 476.25 MHz and 477.400 Mhz. These are known in Australia as standard UHF radios.

We have seen UHF radios from other countries, which purport to transmit over the same frequency, however the channel spacing is different, so it is recommended that you purchase one in Australia.

Optional preparation

Fuel Tank Pan

Fuel tank pans are another point of conjecture. Some people swear by them, some people swear at them.

If you do fit a fuel tank pan, you need to fit it so that the leading edge is not exposed. This can be achieved by cutting the pan to match the crescent shape of the chassis and sitting the pan on top of the lip on the chassis.

Ignition

The ignition wires for the ignition switch have been known to bounce off on corrugations and it is suggested that you tie them up.

The steering lock can fail on corrugations, engaging the lock while in transit. Some people prefer to remove this device.

Body

As you like it, but it is essential to keep weight down. Fit heat shielding around the fire wall and floor to keep the heat out. Make and fit a shade cloth roof under the existing roof for cooler open top driving. Some make the PO modifications to the guards. Some remove plastic side and rear glass and replace with perspex.

Air Cleaner

Make sure it is solid, air, tight, no leaks, sealed, secured down properly. And that it does not suffer from fatigue and vibration.

If it doesn’t measure up, then fit a UNI FILTER onto the air cleaner inlet. This is a special oil soaked foam rubber tubular shaped filter, held on with a pipe clamp or cable tie. This will have to be washed out frequently in severe dusty conditions in mineral turpentine or petrol and re-oiled.

Gooseneck air intake fitted with Unifilter and angled to accommodate spare tyre. Second stage filter sock added on dirt roads. Plastic bottle cut to take breather tube.

The demister tubes have been removed and the outlets blocked.

Spare tyre is supported on threaded rod cased in plastic tube. Rod fits through existing lugs on top of mudguards and is secured with Nyloc nuts and washers. This was fitted by David Gries and the arrangement survived the latest Raid survey of the full route plus extra travel – total 15,100km.

Mirrors

Due to the tracks we travel on, side mirrors are frequently smashed. Some prefer to remove them, and others suggest taping them with clear tape to minimise the damage.

Spinifex and bushes crowd the track on the edge of the Great Victoria Desert